The luxury car bumper repair industry has seen a dramatic transformation, driven by manufacturers' high standards and consumers' expectations. Traditional methods have been superseded by advanced technologies like 3D printing, laser welding, and CAD, enabling precise repairs that match factory-original parts in both aesthetics and performance. These innovations cater specifically to the meticulous craftsmanship associated with luxury vehicles, enhancing customer satisfaction while reducing costs and turnaround times.

The world of luxury car bumper repair has undergone a remarkable transformation, evolving from traditional methods to embrace advanced technologies. This article delves into the intricate journey of precision crafting, exploring how cutting-edge innovations are reshaping the industry. From 3D printing’s role in creating bespoke parts to laser welding’s strength and CAD software’s precision, these technologies redefine restoration.

Furthermore, we shine a spotlight on sustainable practices gaining traction in luxury car bumper repair, highlighting eco-friendly materials and initiatives that promote environmental stewardship.

- The Evolution of Bumper Repair: Unlocking Precision in Luxury Cars

- – Exploring the shift from traditional to advanced repair techniques

- – Impact of luxury car manufacturers' standards on bumper repair innovation

The Evolution of Bumper Repair: Unlocking Precision in Luxury Cars

The evolution of bumper repair techniques has significantly transformed the landscape of luxury car upkeep. In the past, fixing a damaged bumper on an upscale vehicle meant relying heavily on manual labor and traditional methods, often resulting in time-consuming and imprecise repairs. However, advancements in technology have unlocked unprecedented levels of precision in luxury car bumper repair.

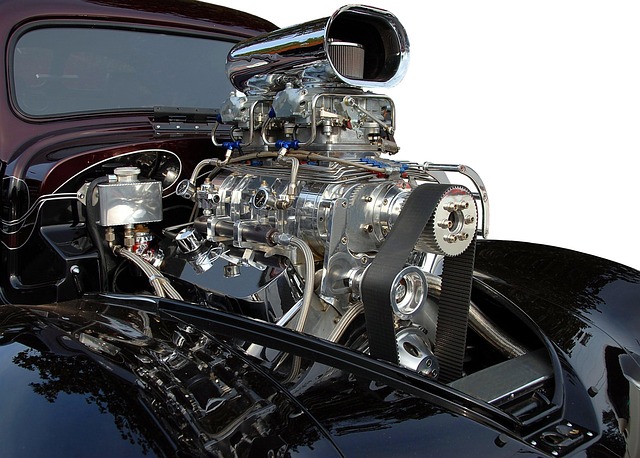

Modern auto body restoration techniques, such as computer-aided design (CAD) and 3D printing, allow for exact replication of a car’s original bumper components. This ensures not just a visually identical repair but also maintains the structural integrity of the vehicle. Moreover, laser welding and advanced adhesives have revolutionized fender repair, enabling faster healing times and stronger bonds that mirror the quality of factory-original parts. These innovations cater specifically to the meticulous craftsmanship required in luxury car body repair, ensuring that these vehicles not only look their best but also maintain their high performance standards.

– Exploring the shift from traditional to advanced repair techniques

In the realm of luxury car bumper repair, a significant evolution has taken place over recent years, marking a shift from traditional methods to advanced repair techniques. This transition reflects the increasing demand for precision, quality, and aesthetics in the luxury automotive sector. Consumers no longer settle for basic repairs; they expect their vehicles to look as good as new, aligning perfectly with the meticulous craftsmanship associated with luxury car brands.

Advanced technology has played a pivotal role in this transformation, introducing innovative solutions that enhance both the efficiency and effectiveness of bumper repair. From 3D printing for custom parts to laser scanning for precise measurements, these modern tools enable auto detailing specialists to restore damaged car bodywork to its original form. The integration of advanced technologies not only accelerates the repair process but also ensures unparalleled accuracy in color matching and surface smoothness, ultimately catering to the discerning tastes of luxury car owners.

– Impact of luxury car manufacturers' standards on bumper repair innovation

Luxury car manufacturers set high standards for their vehicles, including meticulous craftsmanship and cutting-edge technology. These stringent requirements have significantly driven innovation in the field of luxury car bumper repair. With each new model year, consumers expect their cars to not only maintain superior aesthetics but also withstand potential dents and damage with minimal scarring. This has prompted auto dent repair specialists to adopt advanced technologies that mirror the precision and sophistication found in original equipment manufacturing (OEM).

As a result, modern bumper repair processes often involve sophisticated tools and techniques such as laser welding, computer-aided design (CAD), and 3D printing. These innovations enable precise restoration of damaged bumpers to their original factory specifications, ensuring not only visual perfection but also structural integrity. Moreover, integrating these advanced technologies into auto body restoration has led to faster turnaround times, reduced costs, and improved overall customer satisfaction for luxury car owners seeking bumper repair services.

The evolution of luxury car bumper repair reflects a harmonious blend of advanced technology and meticulous craftsmanship. By adopting innovative techniques such as laser welding, 3D printing, and precision machining, repair shops are able to meet the stringent standards set by luxury car manufacturers. These cutting-edge methods not only ensure structural integrity but also preserve the aesthetic beauty of these high-end vehicles. As technology continues to advance, we can expect even more sophisticated repairs, making luxury car bumper repair a testament to modern automotive engineering and meticulous attention to detail.